Perfect Patterns is proud to

employ more than 100 skilled craftsmen whose commitment to excellence shows in their longtime dedication to building your solutions. Combine that with our state-of-the-art equipment, and the formula is engineered for superior results.

CAPABILITIES/EQUIPMENT

Having the right machinery is as important as having the right people. At Perfect Patterns, we have both. We consistently update our CAD/CAM technology because we know it’s important to be able to work with anything you have.

MACHINES

Horizontal

- (1) Makino A51 — 15.74″ Pallet (400mm) — 4th Axis

- (1) Makino A61 — 19.7″ Pallet (500mm) — 4th Axis Robotic Load

- (1) Makino A71 — 19.7″ Pallet (500mm) — 4th Axis Robotic Load

- (1) Makino A81 — 31.5″ Pallet (800mm) — 4th Axis

- (1) Makino A88 — 31.5″ Pallet (800mm) — 4th Axis

- (1) Haas EC630 — 40″ x 35″ Pallet (630mm) — 4th Axis

- (1) Haas EC1600YZT — 60″ x 50″ x 40″ — 4th Axis

- (1) Haas EC1600 — 60″ x 50″ x 30″ — 4th Axis

- (2) Devlieg Boring Bar — 72″ x 48″ x 16″ — 4th Axis

Vertical

- (1) Viper PMC-3122 — 122″ x 87″ x 73″

- (1) Eumach DM-2000 — 85″ x 65″ x 29″

- (2) Viper Pro-2150 — 81″ x 65.0″ x 36″

- (2) DMG DMU-105 Monoblock — 55″ x 48″ x 29″ — 5th Axis

- (6) Haas VF-8 — 64″ x 40″ x 30″

- (1) Eumach — 104″ x 35″ x 40″

- (2) Haas VF-6 — 64″ x 32″ x 30″

- (12) Milltronics RH30 — 60″ x 30″ x 28″

- (1) Roders RP800 — 34″ x 27″ x 23″

- (1) Haas VF5-XT — 60″ x 26″ x 25″

- (2) Haas VF-5 — 50″ x 26″ x 25″

- (2) Hass VF-3YT/50 — 40″ x 26″ x 25″

- (1) Eumach — 47″ x 25″ x 26″

- (4) Milltronics RH25 — 60″ x 25″ x 24″

- (2) Haas UMC-750 — 30″ x 20″ x 20″ — 5th Axis

- (2) Haas VF2SS — 30″ x 16″ x 20″ — Robotic Load

- (1) Haas VF2YT — 30″ x 20″ x 20″ — Robotic Load

- (2) Milltronics MD20 — 40″ x 20″ x 20″

- (2) Fadal 4020 — 40″ x 20″ x 20″

|

Lathes

- (3) Murata Muratec MW400 w Gantry — 15.51″ Dia x 9.41″ — Robotic Load

- (2) Okuma 2SP-V40 Dual Spindle — 15.75″ Dia x 17.72″

- (1) Haas SL-40 — 25.5″ x 44″

- (2) Haas SL-30 — 15″ x 20.5″

- (2) Poreba — 30″ x 65″

Inspection

- 2.5m 7 axis Roemer Arm, PC DMIS, Scanning & Probing +/- 0.0011″

- 2m 7 axis Roemer Arm PowerInspect 2012/R2 +/- 0.0010″

- Mitutoyo CMM F1106 — 40″ x 36″ x 20″ +/- 0.00001″

- Hexagon SF 7,10,7 — 17.8″ x 39″ x 17.8″ +/- 0.0001″

- Elm Systems CMM — 120″ x 72″ x 72″ +/- 0.0025″

- Elm Systems CMM — 60″ x 48″ x 48″ +/- 0.0025″

Metal Shop

- (12) Radial Arm Drill, up to 8′ Swing

- (7) Manual Bridgeports

- (7) Manual lathes, swing up to 35″

- 150 Ton Spotting Press

- Bearing Presses

- Production Assembly and Packaging lines

- Assorted Supporting Equipment

|

SOFTWARE

- ProEngineer

- Unigraphics

- PowerShape

- Solidworks

- MasterCAM

- Catia

- Mechanical Desktop

- PowerMill

TOOL ENGINEERING

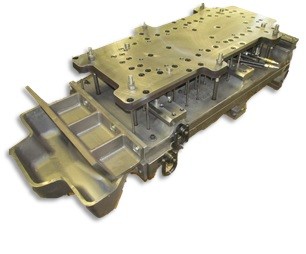

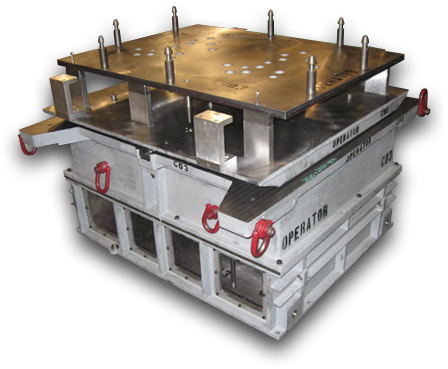

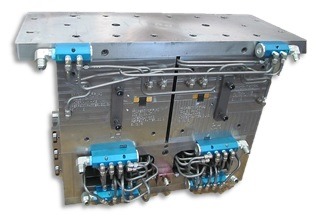

Perfect Patterns is capable of fully engineering your foundry tool, be it a permanent mold with hydraulic slide pieces or a 15,000 lb multi-cavity sand corebox. Our experienced engineers make it easy to reverse engineer your old part into a new, up-to-date tool. Questions are addressed proactively, and tools are built to operate flawlessly upon arrival to your facility. We won’t tolerate anything less.